Fabricating Face Shields – Yes You Can!

Does your medical community need face shields? Here’s how to help.

Nurses wearing face shields fabricated by ATinNH

For adequate protection from hands and airborne novel coronavirus particles, hospital workers and others providing direct care are donning plastic face shields in addition to masks. This element of Personal Protective Equipment (PPE) is in short supply and, as with cloth masks, various “maker recipes” are emerging.

Naturally, our State AT Program network is getting in on the action. Below are instructions from the New Hampshire AT Program (ATinNH) and the Utah AT Program (UATP). Each takes a different approach to solving the challenge of mass-producing face shields. If you want to help and are tired of sewing cloth face masks, consider this new way to contribute much-needed PPE.

ATinNH – Make a Face Shield in Under a Minute

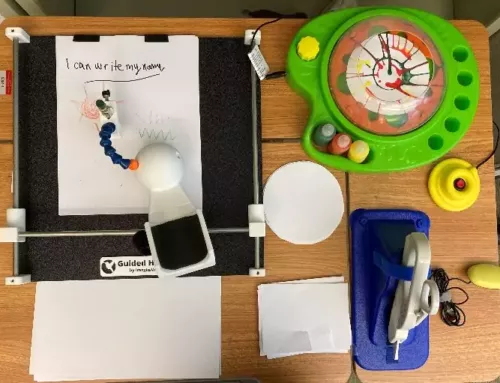

Therese Willkomm, Ph.D., is director of ATinNH and a master maker of assistive technology for individuals with disabilities. Her solutions always strive to be three things: affordable, customizable and “just-in-time.” Creating and propagating an effective face shield fits in her wheelhouse. This shield, she says, is a good deterrent from bringing hands to face, one way the new coronavirus is known to spread.

Here’s what you need:

- 24 inches of double-sided Loop (or Veltex by Velcro):

- One 8.5 x 11-inch Transparency Sheet (such as Staples transparency film);

- 11 inches of 3/4-inch self-adhesive hook (such as Velcro Hook 88);

- 1 x 1.5 inches of Velcro Brand One Wrap

To assemble:

- Adhere the strip of hook to the transparency film, centered along the edge of the sheet’s long 11-inch side.

- Adhere the 24 inches of double-sided Loop, centered on the strip of hook. This is your headband.

- Adhere the piece of One Wrap to the exterior side of one end of your headband leaving an overlapping tab.

- Wrap around your forehead, and fasten the tab at your desired tightness!

Dr. Willkomm posted her video to YouTube on March 29th. Over the following week, it logged 704 views and she heard from two nurses in need of the solution. She quickly organized a team of volunteers and fabricated 50 face shields in one day. To date, 155 have been distributed to doctors, hospitals, group homes, and long-term care facilities in three states. Doctors at one hospital have since requested more.

Dr. Willkomm is the author of multiple volumes of Assistive Technology Solutions in Minutes. This face shield, however, may be assembled (with pre-cut materials) in just 45 seconds (not that anyone’s counting!) At present she is also working on a new solution, applying Remo One (tape) to ski goggles (which are popular with doctors). The tape provides an aggressive seal on one side and a removable seal on the other so transparencies may be replaced or cleaned as needed.

Utah’s Face Shield Accommodates Eyeglasses and Goggles

At the same time that ATinNH was crafting a super-fast face shield, the Utah AT Program (UATP) was also brainstorming how to help address the face shield shortage. UATP Director Sachin Pavithran, Ph.D, says their state is working to stockpile shields and their program has started conversations with the Department of Health and local hospitals.

Utah’s face shield (ordinarily worn also with a face mask)

Coordinating with the College of Engineering at Utah State University, UATP is starting with a goal to build 550 face shields. Like NH’s, their solution also makes use of 8.5 by 11-inch transparency film. The difference is the headband is solid plastic and made with a 3D printer, a CNC router, or a laser cutter. Download the design files for Utah’s face shield from thingiverse.com

Volunteer Mike Stokes and his son, Jonathan, remixed an open-source design to come up with a version that could accommodate glasses or goggles. They emphasize that this hard-plastic fabrication is easy to sanitize, rendering them “medical grade.”

The program is now seeking volunteer makers to take these patterns and start producing. The program is accepting donations of completed shields and of unused 8.5 X 11-inch clear transparency film/overhead projector sheets at their fabrication lab in Logan. Read more about UATP’s effort at their blog.

Let’s get making!

Monthly Blog Digest

Search the blog

State AT Program Blogs

California

Florida

Indiana

Kentucky

Louisiana

Maryland

Massachusetts

Michigan

Montana

North Carolina

North Dakota

Utah

State AT Program Blogs

The AT3 Center, the Association of AT Act Programs (ATAP), and the Administration on Community Living (ACL) make no endorsement, representation, or warranty expressed or implied for any product, device, or information set forth in this blog. The AT3 Center, ATAP, and ACL have not examined, reviewed, or tested any product or device hereto referred.